Selecting backsheets and encapsulants is a crucial step in designing photovoltaic modules. These materials play an essential role in protecting solar cells from environmental conditions while ensuring the module's performance and durability. Here are the key properties to consider when selecting them:

- Water Vapor Transmission Rate (WVTR, [g/m²/day]): Encapsulants slow down the infiltration of water vapor but do not completely prevent it. Strong and durable adhesion to solar cells, glass, or other materials is essential to avoid water accumulation, prevent acid-induced corrosion, and maintain electrical insulation. This issue is particularly present for TOPCON cells, for which the use of POE is recommended.

- Volume Resistivity (ρ, [Ω·cm]): Low resistance values in encapsulant materials are associated with high leakage currents and potential-induced degradation (PID). High resistivity helps to significantly reduce the occurrence of PID. For backsheets, it is important to keep in mind the thickness limit of 300 microns to meet the requirements of the IEC 61730 standard for a 1500V certified module.

- Optical Transmittance (T, [%]): The amount of light passing through a material is crucial. High transmittance and reflection improve solar cell efficiency. The UV stability of the encapsulant is also crucial to maintain high transmittance over time, as yellowing or browning can seriously affect this property.

- Reflection (R, [%]): The amount of light reflected by the surface is essential for opaque backsheet module architectures.

Encapsulants

Encapsulants in solar modules have several crucial functions: maintaining the system in place to support mechanical stresses, electrically insulating the solar cells, and protecting them from the external environment. The main types include thermoplastic and thermosetting polymers, which are currently the most used category.

Commonly used materials include thermosetting : POE, EPE, and EVA. For optimal cell protection, they must follow a precise heating and cooling cycle (this point is verified by measuring the encapsulant gel rate during production).

Their Main Attributes Are:

| Attributes | EVA | EPE | POE |

|---|---|---|---|

| PID Resistance | Depends on formulation | Moderate - Due to POE layer | High |

| WVTR Sensitivity to Moisture | 40 g/m²/day | 20-30 g/m²/day | 4-6 g/m²/day |

| Chemical Reactivity | Intermediate | Reduced acid production | |

| Application | PERC Cells; Glass-Backsheet or Glass-Glass Modules | Producer study for adaptation to Topcon | TopCon, HJT |

| Price | Low | Medium | High |

In summary:

- EVA (Ethylene-Vinyl Acetate) is predominant due to its satisfactory properties and reasonable cost.

- POE (Polyolefin Elastomer) is gained popularity as an alternative to improve protection.

- EPE (Expanded Polyethylene): Composed of three layers of EVA/POE/EVA. It is an economical and technical alternative to the other two.

BACKSHEET

To protect their structure from climatic hazards, solar panels are equipped with glass or composite polymer sheets called BACKSHEET. These are usually three-layer constructions: PVF / PET / PVF with a thickness of 280–400 μm.

PET (Polyethylene Terephthalate) electrically insulates and provides mechanical stability, while PVF (Polyvinyl Fluoride) protects against atmospheric agents such as humidity, dust, UV, etc. The PVF layer also promotes adhesion with the encapsulant layers. Other alternative materials to PVF include PA (Polyamide) and PVDF (Polyvinylidene Fluoride).

PVF and PVDF fluoropolymers are part of substances dangerous to humans. There are concerns about their toxicity and their effects on the environment and human health, whether during production, use, or end-of-life processing.

However, removing these layers will result in accelerated yellowing of surfaces due to UV exposure and reduced moisture protection. To avoid choosing between quality and health, several companies are developing fluorine-free alternatives (see table below).

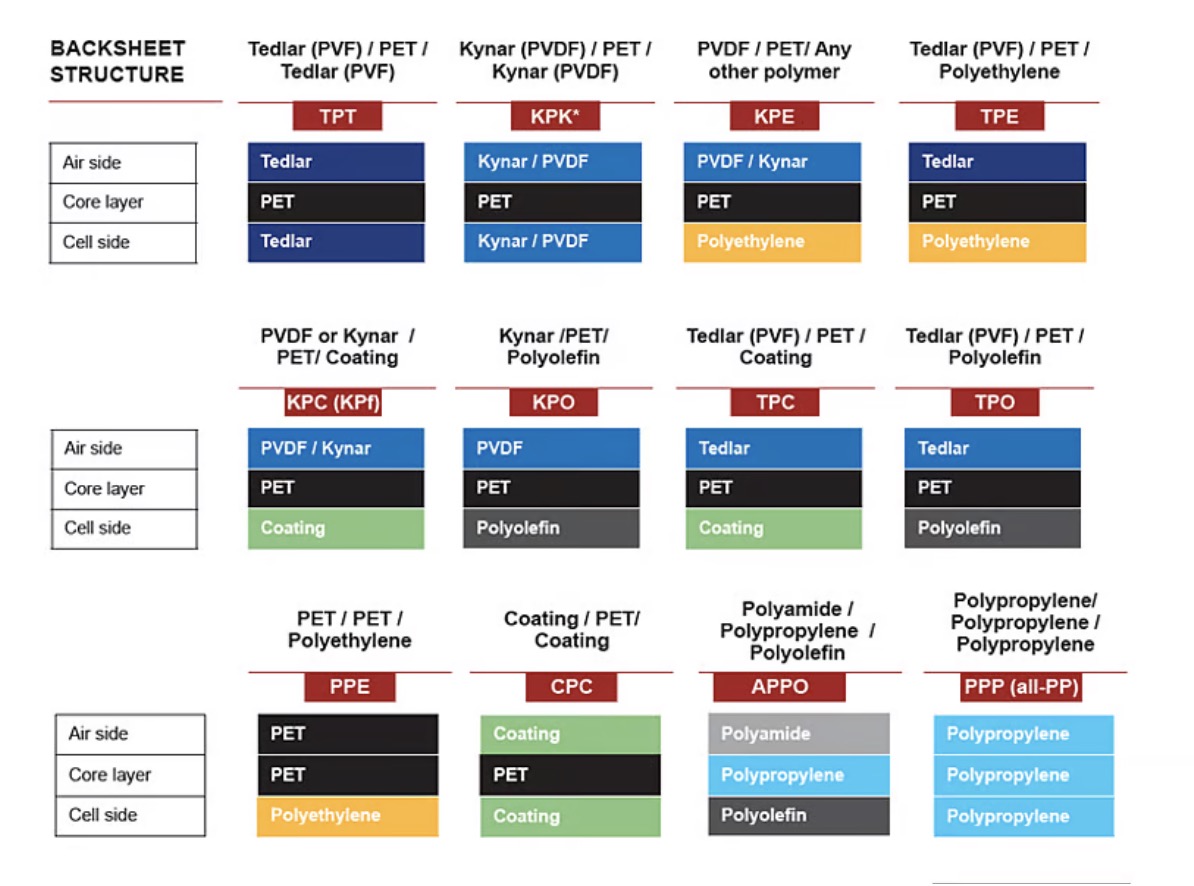

Ultimately, there are almost as many backsheet variants as there are producers: the list from TaiyangNews can illustrate this. Regardless of the chosen technology, it is essential to ensure that lifespan tests have been conducted comprehensively.

fig - many type of encapsulants

Fig 1. Possible Constructions for Backsheets

For example, see the PV magazine article (link below) on advanced polymer coated backsheets (CPC); the core is still PET, and the two external layers have replaced fluoropolymers with other formulations. These assemblies are gaining ground due to reduced costs, but there are concerns about their long-term reliability due to the lack of comprehensive test data.

Once the product is chosen, a detailed visual inspection at the end of production is a crucial step to ensure the quality and integrity of the product. This inspection helps avoid numerous defects that could compromise the performance and aesthetics of the final product. The CCAC teams are present to identify and prevent defects such as thickness inconsistencies, air bubbles, foreign particles, scratches, or surface haze.

Considering these general aspects, I present here a quick review of the main producers and the availability of fluorine-free products. Chinese factories prioritize the fluorinated market but are not opposed to producing fluorine-free products. European companies, on the other hand, are more environmentally conscious and thus quicker to offer fluorine-free products.

The list below is not intended to be exhaustive but to provide an idea of the current situation, knowing that factory news is constantly evolving.

| Manufacturer | country | ENCAPSULTATION | BACKSHEET | non-fluoropolymer |

|---|---|---|---|---|

| Borealis | Austria | X | X | |

| Coveme Spa | Italy | X | X | |

| Crown advanced material co.,ltd | China | X | X | |

| Cybrid Technologies Inc., | China | X | X | X |

| DuPont Teijin Films (DTF) | USA | X | ||

| Endurans Solar (formerly DSM) | US | X | X | |

| Féron GmbH & Co. KG, | Germany | X | X | |

| First PV Material Co., Ltd., China | China | X | X | X |

| Hangzhou Foremost (Fumotech) | China | X | X | |

| HIUV New Materials Co., Ltd., | China | X | ||

| HUITIAN | China | X | X | |

| Jiangsu Sveck New Material Co., Ltd | China | X | ||

| Jolywood (Suzhou) Sunwatt Co., Ltd., | China | X | ||

| Lucky Group Corporation, | China | X | ||

| Renewsys | India | X | X | |

| Shingi Urja Pvt. Ltd | India | X | X | |

| SINOPONT | china | X |

We are open to any question for détails on

Sources:

Backsheet global report

https://taiyangnews.info/technology/so-many-backsheet-structure