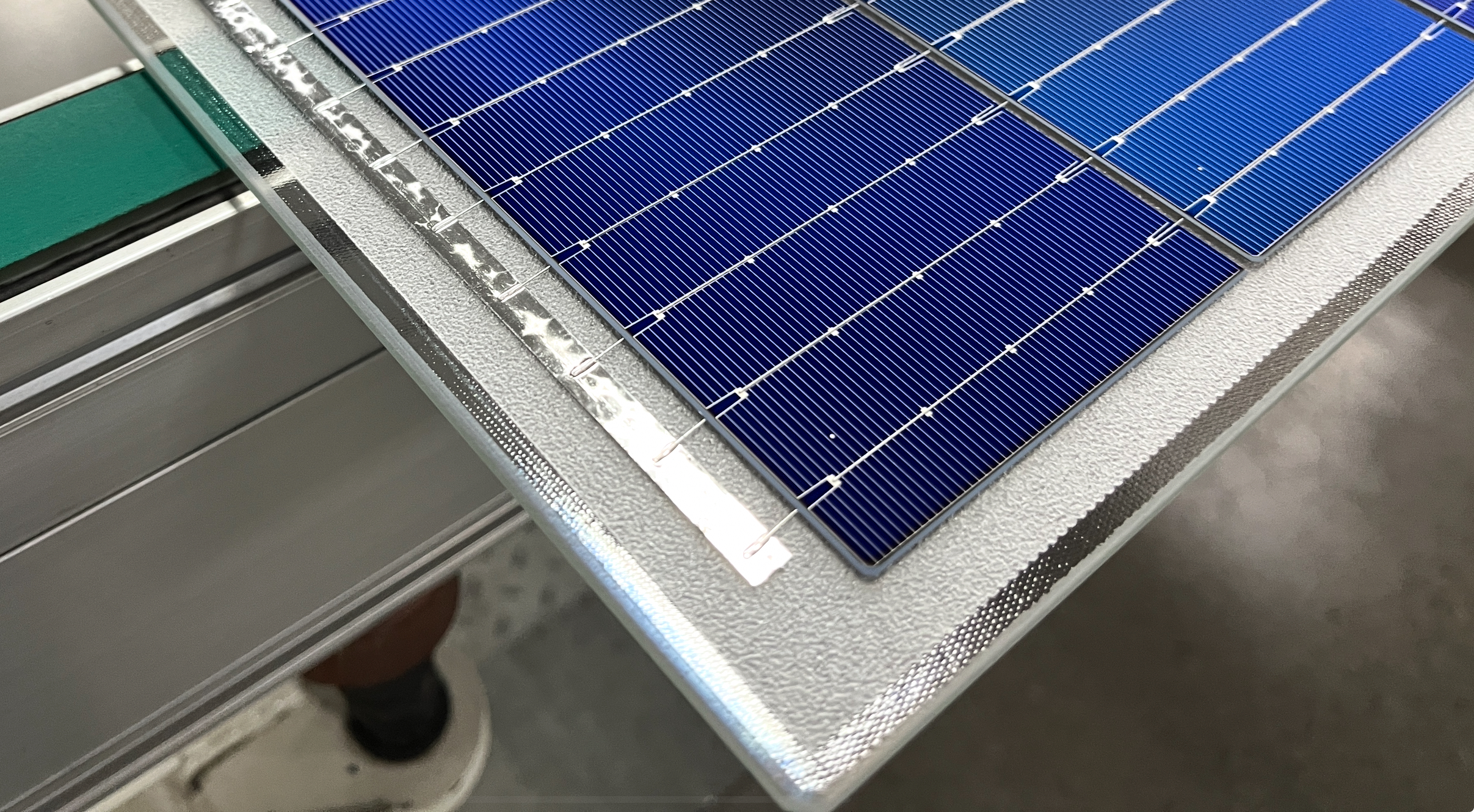

Solar glass typically comes in the form of flat or float glass, with typical thicknesses ranging from 1.6 to 3.2 mm. It is essential to use glass with low iron content to ensure maximum light transmission. Without this property, up to one-third of the light hitting the solar cell would be deflected, resulting in reduced efficiency. In addition, using glass combined with an anti-reflective coating, we can significantly enhance efficiency and minimize energy loss.

When selecting solar glass, key considerations include:

- Light Transmission: Ensure the glass allows maximum light to pass through.

- Anti-Reflective Coating (ARC) or Texturing: Reduce light reflection and increase efficiency.

- Tempering and Thickness: Confirm durability and performance.

General Production Process of Flat and Float Glass

Flat glass, also known as 'plate glass' or 'sheet glass', is easy to treat, temper, coat, or infuse with texture or color.

The production process involves mixing silica sand, soda ash, limestone, and other additives, which are melted in a furnace at high temperatures (around 1500-1600°C). The molten glass is then shaped into rolls and gradually cooled in a controlled environment to relieve internal stresses and increase strength. Finally, it is cut into the desired sizes and shapes, with edges polished or treated as necessary.

Float glass, similar to flat glass, is a flat panel made from silica sand and other organic elements. What sets float glass apart is its production process and quality.

Raw materials are first mixed and melted, then floated on a 'float bath' made of tin, ensuring planarity and full control over thickness. The material is then slowly cooled and formed into a smooth, ribbon-like format before being rolled onto conveyor belts for polishing. Float glass surfaces are exceptionally smooth and uniform, with minimal distortion compared to lower-quality glass types.

However, the initial part of the production may yield non-qualitative products, resulting in large rejects that solar producers must discard or sell at a low cost. The goal is to have a float glass production line with high-purity silica sand to reduce iron and nickel content. Ideally, the iron content should be lower than 150 ppm (generally between 80-100 ppm), compared to common glass, which has about 700 ppm.

The final result is a transmission rate for solar glass of over 94%, compared to 68-74% for standard insulating glass. Triple and thick glasses are slightly less bright than double glasses, and sunscreen or tinted glass will have a reduced light transmission rate of 30% or even 20%.

Attention: Some suppliers might use antimony (antimoine) to increase transmission, which is harmful to health.

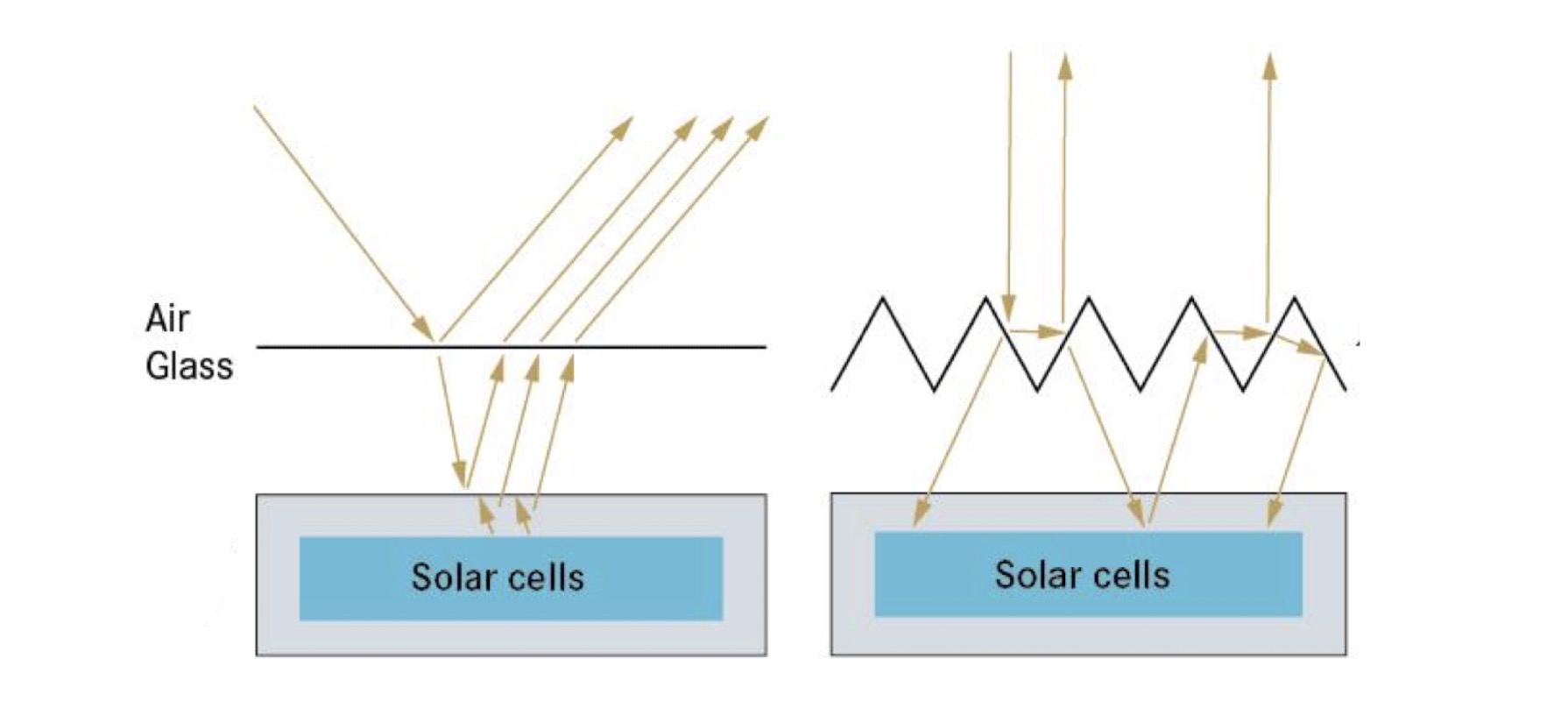

Coating or Texture to Enhance Reflection

In addition to transmission, having a texture or anti-reflection layer is equally important.

Texture is created on glass by pressing a pattern onto the glass before cooling, typically using a pyramidal structure, which increases the amount of light trapped by the glass.

fig1 -

Textured solar glass enhances efficiency by reducing light reflection and increasing light transmission through re-incident light on its raised surface facets. It could also minimize glare, improving aesthetics and safety, especially in high-traffic areas. However, textured glass's uneven surface can eventually trap dirt.

ARC (Anti-Reflective Coating) glass is formed through the deposition of a thin, multi-layered film. It is composed of various materials, each with specific chemical components that contribute to their optical and mechanical properties. Common materials include silicon dioxide, titanium dioxide, magnesium fluoride, zirconium dioxide, and aluminum oxide.

Because this coated surface is now plane and not textured, the ARC coatings will not create the same dirt mechanisms as the texture. However, ARC coatings come with some drawbacks, especially concerning the color and uniformity of the glass. Here are the main issues:

- Color Shift: ARC coatings can sometimes cause a shift in the perceived color of the glass. This is because the coating itself can have a tint or hue that alters the way light is transmitted through the glass.

- Non-Uniform Thickness: Achieving a perfectly uniform thickness of the ARC coating across the entire glass surface can be challenging. Variations in thickness can lead to non-uniform optical properties, such as uneven light transmission and reflection.

This can result in areas of the glass that appear darker or lighter than others, affecting the visual quality and performance.

Special Note on TCO Transparent Conductive Oxide Glass

TCO (Transparent Conductive Oxide) conductive glass is a specialized glass substrate that has been coated with a transparent conductive film. This type of glass is primarily used in thin-film photovoltaic (PV) applications and the recent 4T Perovskite module that we discussed in this article (click here for perovskite details). Key features of TCO conductive glass include a high transmission rate and conductivity. Main types of TCO glass conductive glass include:

- ITO (Indium Tin Oxide) Glass

- FTO (Fluorine-doped Tin Oxide) Glass

- AZO (Aluminum-doped Zinc Oxide) Glass

fig2 -

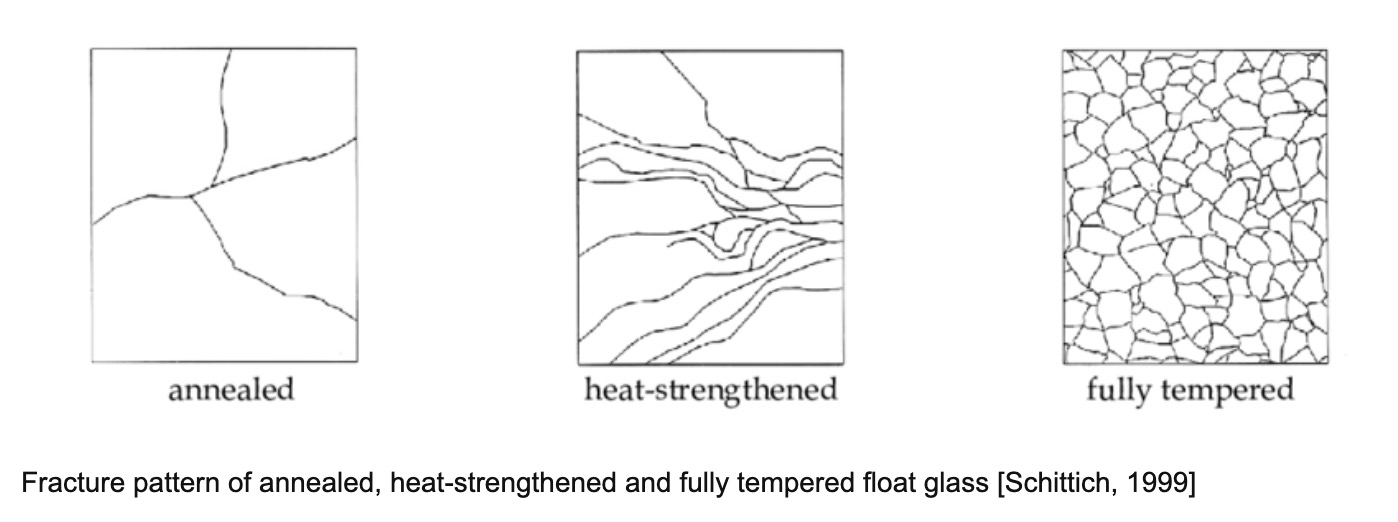

Strengthening Glass Processes

Without proper strengthening, the glass would be fragile and useless in most of our daily applications. Different techniques exist to solve this problem:

Annealed Glass is the simplest process, resulting from the control of temperature at the end of the production process.

- Manufacturing Process: Slowly cooled during the manufacturing process to relieve internal stresses.

- Strength: Basic level of strength, easily breakable.

- Breakage Pattern: Breaks into large, sharp shards.

Heat-Strengthened Glass

- Manufacturing Process: Heated to approximately 650°C and then cooled more slowly than tempered glass.

- Strength: Approximately twice as strong as annealed glass.

- Breakage Pattern: Breaks into relatively large pieces with fewer, less sharp shards than annealed glass.

Tempered Glass

- Manufacturing Process: Heated to around 600°C and then rapidly cooled by blowing air onto both surfaces.

- Strength: Approximately 4-5 times stronger than annealed glass.

- Breakage Pattern: Breaks into small, blunt pieces, reducing the risk of injury.

Chemically Strengthened Glass

- Manufacturing Process: Submerged in a bath of potassium salt at around 380°C, resulting in ion exchange between sodium ions in the glass and potassium ions in the bath.

- Strength: It is 15-20 times stronger than annealed glass and 3-5 times compared to thermal tempered glass. Higher bending strength and lower central tension, offering better force absorption.

- Scratch-Resistance: More scratch-resistant and can withstand higher thermal shocks.

- Breakage Pattern: Breaks into small, rounded fragments, similar to tempered glass, but can have larger pieces depending on the treatment.

Current Trends and Considerations on Strengthening

Chemical strengthened glass excels with a minimum thickness of 0.5mm, while thermal tempering struggles below 2.5mm. It can take any shape or size without limitations, be bent and laminated precisely without defects, and be easily cut and installed without breaking. However, the main drawback is that chemical glass breaks into large pieces, unlike thermal glass's small fragments, making it potentially more dangerous when broken.

Currently, glass-glass modules typically use 2mm thick glass and are moving towards 1.6mm to reduce costs. The weak point in these modules is the connection holes left for the junction box assembly. Cutting can cause small damage to chemically strengthened glass (loses its added strength within the region of approximately 20 mm of the cut), and thermal tempered glass can break at the cutting point. To prevent issues, glass cutting should always be done before strengthening.

Testing Tempered Glass

To check tempered glass, a fragmentation test must be conducted using a pricker according to the EN 12150 standard. Glass that meets the EN 12150 standard breaks into numerous small pieces, with at least 40 fragments within a 50 mm x 50 mm square, and no fragment longer than 100 mm. The best-tempered glass can have up to 300 fragments.

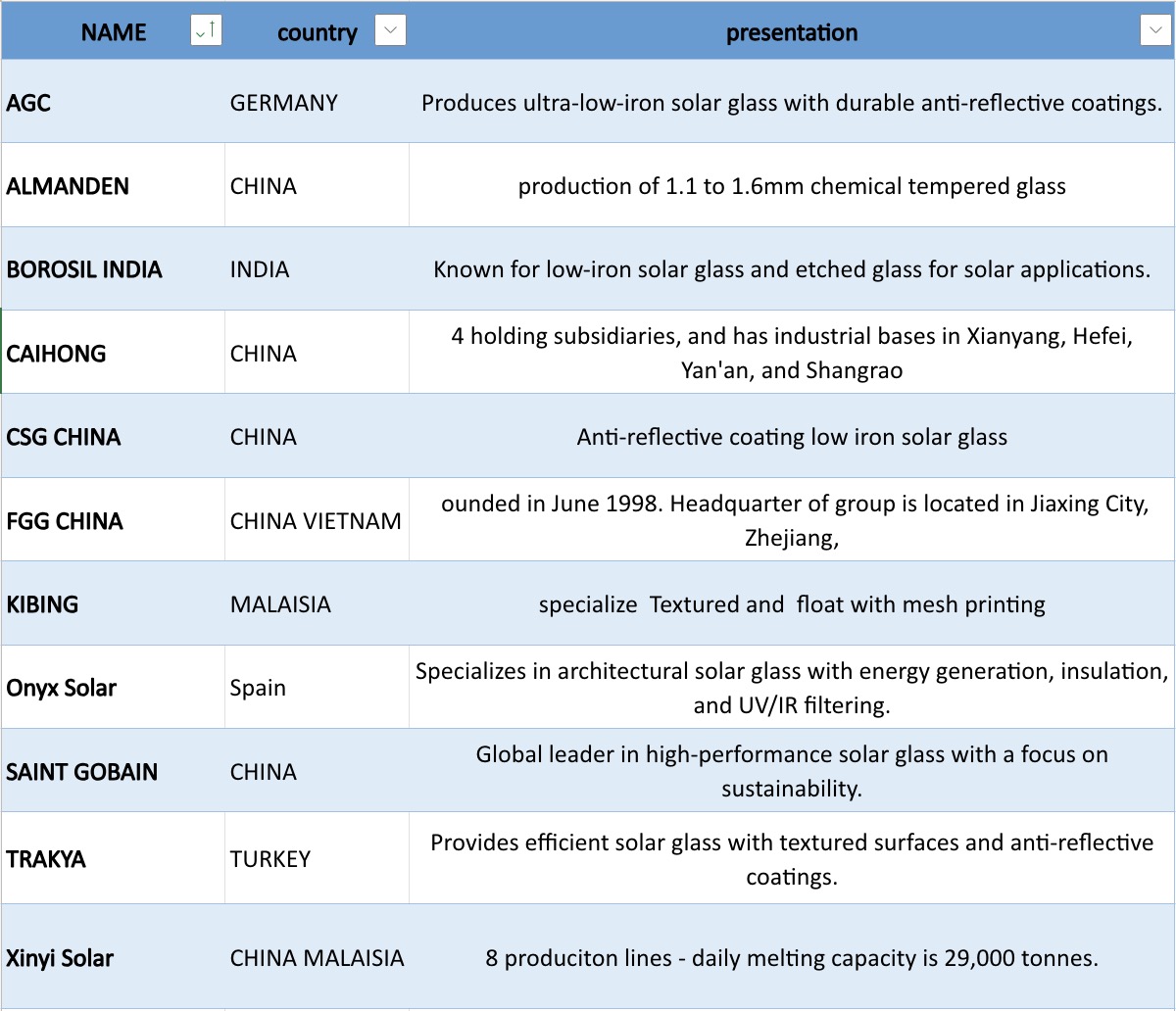

Sourcing

When considering sourcing, we can follow the world index of raw material prices to establish the best based on estimation that the production cost of the flat glass is close to the production cost of texturing and coating.

Final point of importance: Glass labeled as solar is currently heavily taxed coming from China: up to 70%. However, furniture glass (super white or regular) or TCO glass is not taxed.

Suppliers and Their Production Bases

fig3 -

Specializing in project-based services, CCAC supports European producer companies with their sourcing activities in Asia. Feel free to contact us for details.

原文 Original posts